Vending machine operation retail business

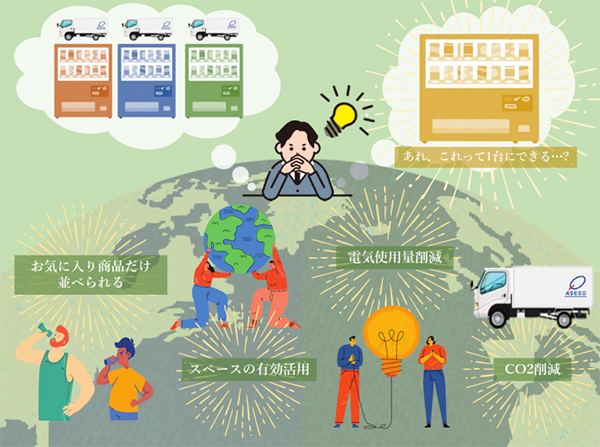

Consolidation of vending machines

We are reviewing the current situation where vending machines from multiple manufacturers are lined up side by side, and are working to reduce power consumption and improve the appearance of the area by consolidating them into one vending machine that handles products from multiple manufacturers.

Introduction of energy-saving vending machines

We have adopted the latest hybrid heat pump vending machines, which reuse the heat generated when cooling beverages and the heat of the outside air for heating, to achieve a significant reduction in power consumption.

Installation of vending machines that accept donations

We operate vending machines that donate a portion of their sales to various organizations. At Aseed Corporation, we have installed vending machines that donate to the Green Fund, and we are promoting environmental conservation activities that donate to the Green Fund. In addition, we are working with various organizations, including those that support crime victims, donate to crime prevention associations, and support guide dog associations.

Installation of vending machines to reduce food loss

In several locations, including municipal facilities in Shibukawa City, Gunma Prefecture, vending machines have been installed that sell beverages that are nearing their best-before date or have become surplus stock at a lower price than usual.

Other initiatives in the vending machine retail business

- Switching to LED lighting in offices and warehouses

- Reducing fuel consumption by adopting a flexible working hours system for route staff and avoiding busy periods when traffic is congested

- Installing solar power generation equipment on the roof of the warehouse at the Fukuyama branch of Asseed Co., Ltd. and selling the electricity generated to power around 100 vending machines

Beverage Manufacturing Business

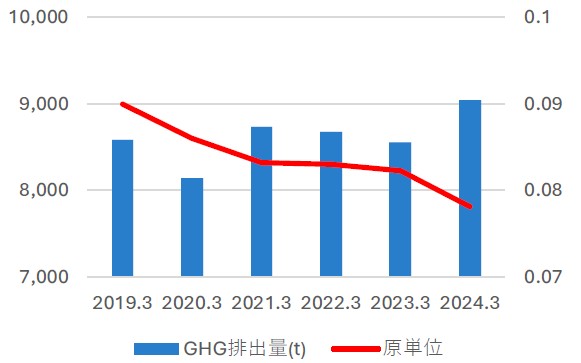

Trends in GHG emissions from Beverage Factory

This is a graph showing the change in emissions from ASEED BREW Co., Ltd. (formerly ASEED BREW Co., Ltd. + Hoshaku Beverage Co., Ltd.). The basic unit is the GHG emissions (t) divided by the production volume (kl).

Although GHG emissions may increase or decrease depending on the production volume, the basic unit shows a decrease in emissions due to factors such as equipment renewal.

Energy conservation through equipment renewal

ASEED BREW Co., Ltd. (formerly ASEED BREW Co., Ltd. + Hoshaku Beverage Co., Ltd.), we are regularly updating our manufacturing process equipment and promoting energy conservation.

| 2021 | Higashihiroshima Beverage Factory | Solar power generation equipment installed on the roof of the product warehouse (used as part of the electricity used in the production line) |

| 2021 | Utsunomiya Beverage Factory | Increasing the efficiency of compressors (reducing the amount of electricity used by 20% on the can line) |

| 2022 | Utsunomiya Beverage Factory | Switching to LED lighting in the factory |

| 2023 | Utsunomiya Beverage Factory | Updating Pastrizer |

| 2023 | Higashihiroshima Beverage Factory | Introduction of a new can line |

| 2023 | Utsunomiya Beverage Factory | Upgrading of wastewater treatment facilities |

| 2024 | Utsunomiya Beverage Factory | Solar power generation equipment installed on the roof of the product warehouse (used as part of the electricity used in the production line) |

New can line

(Higashihiroshima Beverage Factory)

Wastewater treatment facilities

(Utsunomiya Beverage Factory)

Solar power generation equipment

(Utsunomiya Beverage Factory)

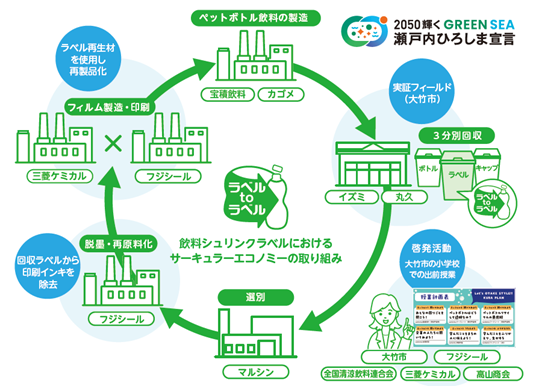

Participation in a resource recycling model project

In response to the “2023 Leading Project to Support Measures for Marine Plastic Litter (including the Reduction of Plastic Use)”, which was publicly sought by Hiroshima Prefecture, the Mitsubishi Chemical Group, as the managing company, made a joint proposal with multiple companies in 2022, and in June 2023, the proposal “Construction of a Resource Recycling Model for the Realization of Horizontal Recycling of Beverage Labels” was selected. Takara Shuzo Beverage Co., Ltd. is participating in this project and manufacturing PET bottle beverages using resource-recycling labels.

Efforts to reduce marine plastic waste

Hoshaku Beverage Co., Ltd. has joined the GREENSEA Setouchi Hiroshima Platform. This platform, which aims to reduce plastic waste in the ocean to zero by 2050, was established by Hiroshima Prefecture and consists of 20 companies and organizations, including beverage and material manufacturers from within and outside the prefecture. Participating companies will establish working groups for each issue and consider and implement specific measures.